Automatic SNG gas Mixers - Propane-Air Mixing Systems

SNG gas Blenders - Propane-Air Mixing Systems

The unique of the MGA series Automatic SNG Blender or automatic LPG air mixer is a gas blending system where LPG (gas propane) and air are automate mixed at high pressure in proportions, producing gas SNG (Synthetic Natural Gas) at the output with required characteristics and is alternative for natural gas for the industry. SNG gas mixture in an automatic LPG air blender has a calorific value equal to methane and biomethane and can replace natural gas in gas supply systems. Air and LPG mixing systems can be used in burners as a direct alternative to natural gas without the need for reconfiguration or replacement of the burner. LPG / Air Blending Systems is precise, safe, and reliable in SNG mixing systems.

We manufacture automatic SNG gas mixers MGA model with pressure ranges from 300 mbar to 12 bar and with capacities ranging lpg air blending system from 250 to 10,000 NM³/h.

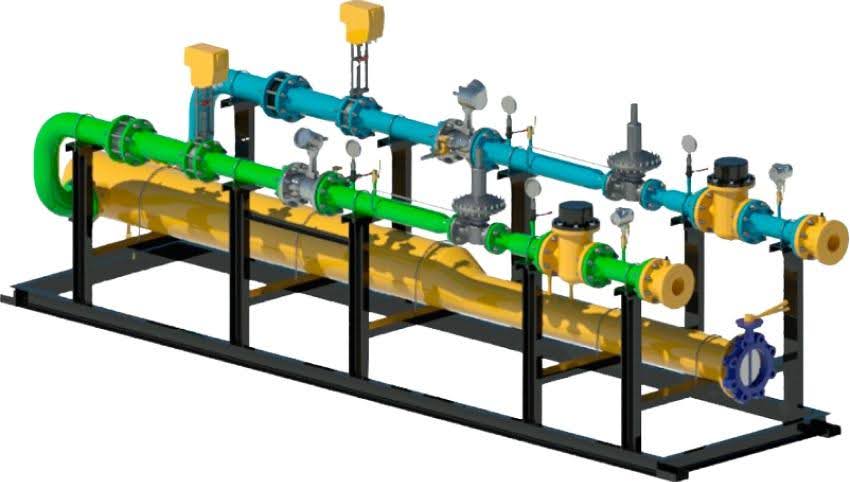

APPEARANCE LPG AIR blending system - Propane Air mixer

Technical Specification LPG mixers

10 unique features of the Gas Blender (Mixer) series MGA from I-MAXIMUM.

1

ADDITIONAL PRESSURE CONTROL at the gas and air inlet and at the SNG outlet using TT temperature sensors with display.

2

INCREASED FILTRATION EFFICIENCY. We use filters that ensure reliable operation of the devices regardless of the gas quality.

3

RELIABILITY OF PRESSURE REGULATORS. Membrane regulators are less demanding in terms of the quality of filtered gas compared to "pilot" system regulators.

4

HIGH MEASUREMENT PRECISION. Built-in pressure and temperature sensors in the VORTEX flowmeter ensure measurement accuracy up to 1%

5

LOUVRED VALVE ENSURES PRECISE REGULATION. The speed and smoothness of valve control are achieved by combining them with a motor drive. Unlike pneumatic drives, the valves can simultaneously provide emergency shutdown.

6

CHECK VALVES PROVIDE ADDITIONAL DEVICE PROTECTION. During operation, they prevent gas from flowing back in case of emergency situations.

7

SAFE GAS MIXING. Thanks to the unique design of the mixing system, there are no pulsations or pressure drops at the SNG blender outlet.

8

PROTECTION AGAINST LIQUID SNG PHASE ENTRY. The temperature sensor in the SNG mixing system prevents the entry of the liquid phase of SNG into the pipelines.

9

GAS LEAK DETECTION. Automatic shutdown of the SNG Blender in case of gas leakage and activation of audio-visual signaling.

10

MULTI-FUNCTIONAL ELECTRIC CONTROL PANEL WITH REMOTE CONTROL CAPABILITY. We monitor over 20 parameters, ensuring safe and reliable operation of the SNG Blender.

You may also be interested

Automatic SNG Blenders

Since industries and utilities push for greater cost-efficiency, flexibility, and supply security in their gas infrastructure, SNG (Synthetic Natural Gas) systems are winning essential recognition. Together with the key components of these systems, the automatic SNG blender system is distinguished as an indispensable solution for steady and reliable gas mixing. It allows for a seamless conversion from natural gas to an LPG (Liquefied Petroleum Gas)-based alternative, ensuring consistent performance in cases of natural gas disruptions or shortages.

The I-Maximum automatic SNG blenders of the MGA line have been developed for autonomous and continuous operation and fully conform to industrial standards for gas mixing and safety. All our SNG blending systems are excellent for peak shaving scenarios and facilities located in territories with insufficient access to natural gas networks.

What Is an SNG Blender?

An SNG blender (also referred to as an SNG mixer) is an automatic or semi-automatic system that mixes air with LPG to generate a synthetic substitute that copies the combustion characteristics of natural gas. The consequent gas mixture, usually known as SNG or synthetic natural gas, can be injected into the current pipeline network or supplied directly to end customers.

This blending procedure requires ultimate precision since improper mixing can bring about poor combustion, damage to applications, or safety risks. Therefore, the I-Maximum blenders include high-accuracy control systems that supervise and adjust the LPG-air ratio in the real-time mode, on consideration of flow, pressure, and calorific value measurements.

The systems are completely compatible with different types of LPG, including propane, butane, or a mix of both. Moreover, they can be adjusted to meet specific gas quality requirements depending on the country or region.

Concept Definition

I-Maximum automatic SNG blenders of the MGA series have been developed for durable performance and convenient deployment. All of them have been preassembled in compact and modular skids that can be easily installed in containerized systems or deployed directly on-site. The technical characteristics of our SNG blending systems comprise the following:

High-precision blending modules employ flow regulators, proportional valves, and control sensors.

Completely automated performance based on PLC (Programmable Logic Controller) and remote supervision capabilities.

Embedded safety interlocks and emergency shutdown systems.

Wide capacity range convenient for small boilers and huge utility-scale installations.

Low maintenance requirements based on the use of corrosion-resistant materials and self-cleaning components.

In addition, all SNG mixers are compatible with standard gas analyzers and flow meters. Moreover, they can be incorporated into existing SCADA (Supervisory Control and Data Acquisition) systems for centralized monitoring. The usual blending accuracy performed by our equipment ranges within ± 1% of the target gas composition. It ensures conformity with combustion parameters for turbines, burners, and the rest of gas-powered applications.

Cases of Application

Automatic SNG blenders are installed in a wide range of applications where flexibility and reliability in fuel delivery are paramount. Whether for emergency substitution or constant SNG supply in off-grid areas, these systems enable continuous performance across various sectors. The usual employment of automatic SNG blenders includes different industrial processes, electric power generating facilities, district heating networks, temporary or mobile installations, and municipal utilities.

By installing an SNG blender, customers can guarantee a resilient energy infrastructure that decreases dependence on a sole fuel source and improves energy security.

System Components and Customization

All our automatic SNG blending systems are subject to configuration based on customer demands. Such a configuration depends upon a few aspects that include required capacity, available LPG delivery technique (liquid or vapor phase), and the expected consumption rate of the synthetic gas. The usual components of an SNG blender skid comprise the following:

LPG inlet and preheating system (if vapor phase is required).

Air compressor or connection to compressed air network.

High-precision gas metering elements.

Air-LPG mixing chamber.

Flow and pressure sensors.

PLC control cabinet with HMI (human-machine interface).

Safety valves, filters, and shut-off mechanisms.

Each SNG MGA mixer can be tailored with optional features that include dual-mode operation (automatic/manual), integration with a chromatograph, and data logging systems. In addition, we provide containerized solutions that house the entire SNG generation module in weather-resistant enclosures for easy deployment and low on-site work.

Compliance, Safety, and Reliability

Safety is overwhelmingly important when it comes to gas blending systems, especially when dealing with flammable PLG and pressurized air. All I-Maximum SNG blenders of the MGA series have been engineered in compliance with international requirements that include PED (Pressure Equipment Directive), ATEX (ATmospheres EXplosibles), and ISO (International Standards Organization) guidelines. Pressure control, leak detection, and automatic shutdown features are standard in all MGA gas mixing models.

Moreover, our company offers full support for start-up and commissioning, personnel training, and preventive inspection scheduling. Our engineering experts support customers to ensure proper deployment and compliance with local regulations and environmental requirements.

Why Choose I-Maximum SNG Blenders?

Our experience in gas system engineering together with attention to operational details stands out the I-Maximum team as a trusted provider of innovative SNG blending solutions. Our mixers have been designed not only for precise performance but also for long-term and reliable operation.

By investing in automatic SNG blenders of the MGA line from I-Maximum, your facility receives the flexibility to stabilize possible supply disruptions, reduce fuel expenses, and leverage energy reliability across your operations.